|

|

Post by chanito on Dec 7, 2006 18:58:58 GMT -5

|

|

|

|

Post by Jasper on Dec 7, 2006 20:14:11 GMT -5

I am considering the Gates belt as Keith and Dan both said it decreases drivetrain noise...what is this mod head you are talking about?

|

|

|

|

Post by chanito on Dec 7, 2006 21:02:06 GMT -5

That is DD's bad influence, he got me daydreaming about a freer breathing head, so i am going to experiment with a head and do some wild mod to the intake track so it will have the carburator facing forward, and a much shorter intake track, hopefully i will have the engine making the most power at 10k and will be able to stay at that rpm all day  If every thing goes well i will make a twin for him  If not i will put the old head back

|

|

|

|

Post by chanito on Dec 8, 2006 7:32:16 GMT -5

I should add that the cooling slots do a wonderful job of keeping the belt case cooler, as i can touch the case after a long ride and is still cool, hopefully that will help the belt to be more eficient for longer  |

|

|

|

Post by Dandy Dan on Dec 8, 2006 9:30:44 GMT -5

Nice stuff Chanito! I can't stop dreaming about that head. I contacted a few places this week about getting some Ti valves and rocker arms made along with new valve springs. I don't really know what I'm looking for at this point but I'd just like to see if upgrading these parts is possible.

About max RPMs, my understanding is that currently we don't really wanna run above 10K because our rockers arms are too heavy and weak so they'd start to flex. If this problem was dealt with via new rocker arms (lighter? stronger? both?), valves (or are the stock ones okay?) and springs (stiffer?) what RPM do you think we could run safely? I just can't stop thinking about how a 600cc sportbike makes 120hp and how I want my 60cc engine to make 12hp. It seems like the biggest factor in the difference is that the 600cc engines rev twice as high so essentially they're having twice as many power strokes. I'd love to get our engines safely up around 12K.

|

|

|

|

Post by Dandy Dan on Dec 8, 2006 15:37:47 GMT -5

Here we go, custom titanium ( or 'super alloy') valves: www.ferrea.com/valves.phpwww.ferrea.com/productlines.php (see blank titanium valves part) I should check if the service manual has the specs on the valves. Am I wasting my time looking into this or are titanium valves a good thing? The lower weight seems good but that's seems about it. Custom rocker arms and springs seems like a bigger deal. I wonder how much these are...$300-$400 for 2 valves maybe. |

|

|

|

Post by I Heard A Rukus on Dec 8, 2006 21:16:32 GMT -5

Here we go, custom titanium ( or 'super alloy') valves: www.ferrea.com/valves.phpwww.ferrea.com/productlines.php (see blank titanium valves part) I should check if the service manual has the specs on the valves. Am I wasting my time looking into this or are titanium valves a good thing? The lower weight seems good but that's seems about it. Custom rocker arms and springs seems like a bigger deal. I wonder how much these are...$300-$400 for 2 valves maybe. The hot set up it stainless valves and ti retainers. I've been looking at this too since our parts are designed the same as most Honda stuff even the cars. Best I can come up with: dratv.stores.yahoo.net/vaspspra.htmldratv.stores.yahoo.net/heavdutvalsp.htmlDo we have a guine pig? KP |

|

|

|

Post by chanito on Dec 10, 2006 17:42:45 GMT -5

"You do not fail if you do not try", i do not think we will encounter valve float at 10k, but if i wanted to go higher i will use roller rocker arms, the roller allows the rocker arm to follow the cam closer and prevents hi speed shock, so there is a lot less stress on the valve and the springs. but i will have to create a shorter intake track to run at that rpm, and then start crossing the "t"s and dotting the "i"s

|

|

|

|

Post by Dandy Dan on Dec 11, 2006 9:37:51 GMT -5

KP, If I knew the dimensions of our stock valves I'd contact ferrea and see what the price is. They do a bunch of stuff inc. Ti and stainless I think. Why is stainless better?

Anyways, the modified head seems like the main part we need to get chugging on...hopefully I can get a head soon. I have no idea what roller rocker arms are so hopefully they aren't too hard to get or expensive.

|

|

|

|

Post by I Heard A Rukus on Dec 11, 2006 11:18:18 GMT -5

KP, If I knew the dimensions of our stock valves I'd contact ferrea and see what the price is. They do a bunch of stuff inc. Ti and stainless I think. Why is stainless better? Anyways, the modified head seems like the main part we need to get chugging on...hopefully I can get a head soon. I have no idea what roller rocker arms are so hopefully they aren't too hard to get or expensive. Stainless has a higher melting temperature so you run less of a risk of burning valves. This is very important at high boost/high compression ratios, especially if you encounter a lean condition (hopefully not). Titanium typically isn't used for valves because it's brittle. Titanium is a powder that is pressed into metal, so it has a tendencey to fracture. This isn't important for small parts like retailers and keepers, or even tubing, but when you get a higher density/mass part like a valve there is a tendency for failure. Honestly for our engine, unless you plan on running boost or NOS we don't need anything but steel valves. The biggest gains will be from larger valves, but I doubt this would flow any better then the 4 valve head, Honda knows what they are doing. That said, the next thing I plan on doing is stiffer springs, they are a must at high RPMs. I wouldn't rev my Civic past 8 untill I did springs and now I have no problems reving it to 10. You need the stiffer springs to help slam the valves shut at high RPMs and keep the valves from staying open, called Float this is the sensation you get from an engine when you rev it higher and it slows down. Best way is to go drive a truck, most trucks lose power at higher rpms because they are built for tourque, where as most cars are opposite. KP |

|

|

|

Post by Dandy Dan on Dec 11, 2006 13:14:55 GMT -5

That said, the next thing I plan on doing is stiffer springs, they are a must at high RPMs. I wouldn't rev my Civic past 8 untill I did springs and now I have no problems reving it to 10. You need the stiffer springs to help slam the valves shut at high RPMs and keep the valves from staying open, called Float this is the sensation you get from an engine when you rev it higher and it slows down. Best way is to go drive a truck, most trucks lose power at higher rpms because they are built for tourque, where as most cars are opposite. Thanks for the valve info...that all makes sense. I was thinking Ti valves might be a good thing because they're lighter which means our rocker arms and springs would have an easier time but that doesn't seem to be a big consideration since no one else has mentioned lighter valves being the key to higher revs. About the valve springs...stiffer springs makes sense with regards to preventing float. However Chanito has been mentioning how our rocker arms likely start to flex at higher RPMs and stronger rocker arms are a key to higher revs. It seems that going with stiffer springs would indeed prevent float but it would add even more stress to our rocker arms so it seems like stronger rocker arms (or those roller ones Chanito mentioned) should be done at the same time. Anyways, You guys know a lot more than I do...I'm just trying to figure out the best direction to head so I really value everyone's input. For now I'm gonna keep working on scaring up an extra head and keep chatting about the springs, rocker arms and valves until we reach a consensus there. |

|

|

|

Post by Dandy Dan on Dec 11, 2006 13:58:03 GMT -5

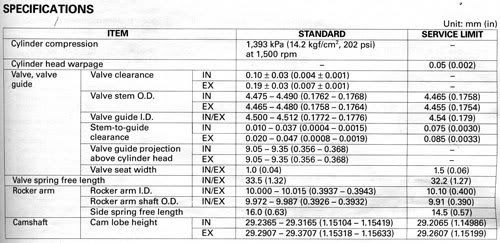

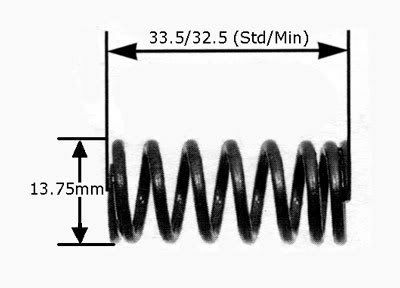

Hmm....stiffer and cheap valve springs. I'm a little scared by the 2nd link that says it works on all 50's and 70's...I find it hard to believe that all 50cc and 70cc bikes use the same dimensions of springs but maybe I'm wrong... Anyways, I'm willing to order those springs since the price is reasonable ($26 or $13 + shipping) but I'd like a bit more info first such as: Are we sure these will fit and not wreck something? And how much stiffer than stock are they going to be? I'd hate to add a bunch of wear and tear for nothing if they're stiffer than need be. According to my trusty service manual, our valve springs have a 'free length' of 33.5mm (service limit = 32.2mm). From there I used the picture in the manual (shown below) to get a rough idea of the width by using proportions. Obviously this isn't the most accurate method but it's all I can do right now. Here's the specs straight from page 8-3 and below that is the spring from page 8-12with the width/length specs added in by yours truly. Notice in the spring pic that the spring is actually progressive and the end with the tighter coil (right end) goes in towards the combustion chamber. Also notice that I typed in the incorrect service limit length as it should read 32.2mm, not 32.5mm...my bad.   Here's a link to some valve springs that are a whole lot more expensive than the ones IHAR linked too....I wonder if these are better or just overpriced? procircuit.rideshop.com/catalog/default.php?cPath=5_141_180Also here's some 50cc 'dirt bike' valves and springs ($23 for em all) on eBay. It seems like a lot of dirt bikes use a 'spring within a spring' method. Is that an upgrade we can do or something specific to their bikes? |

|

|

|

Post by I Heard A Rukus on Dec 11, 2006 16:08:08 GMT -5

The ProCircus ones are nice but you're paying for the name. There is some quality differance but not enough to justify the cost.

On performance Honda engines (B18C5, B16A and B16B, D16...) basically all the ones with VTEC, they use a dual spring system. This is because in order to increase the spring rate you must increase the dia of the metal used in making the spring. The thicker this is the less you will be able to compress the spring. So they use two springs instead, you can use a thinner guage spring material but you have twice as much so it will still be stiffer while allowing compression of the springs so the valve will still open all the way and the cam won't be binding on the compressed spring. If those springs are the same dia, and the same length compressed they will work. Then the only ? is spring rate. They make special tools for this but a quick and nasty way is just a scale or force guage.

KP

|

|

|

|

Post by Dandy Dan on Dec 11, 2006 16:41:30 GMT -5

Your explaination of the dual spring system makes sense...that was nicely explained! Thanks ;D

About our springs...our intake and exhaust springs are the same part which is only $1.86 (According to RonAyers.com) so if it looks like this is going to happen I'll probably just order one from my Honda dealer to measure the spring rate. Determining the spring rate seems harder because I have no idea where to get the tool but springs are normally measured in lbs/inch aren't they (at least my mtn bike is). If so, it seems like I could just balance a known weight on the spring a brick and measure how far it compresses...definately a ghetto method but maybe it would give us an acceptable general idea? or maybe not....would my local bike shop have a tool for this? I'd guess not...

Maybe I'll email those guys at the link you provided and see if they're willing to provide a few specs on their springs.

|

|

|

|

Post by chanito on Dec 11, 2006 21:25:26 GMT -5

Let me state before hand that this is just my opinion based on my personal experience, but valve float is the phenomena that happens when the valve does not close fast enough and stay open when it should be close, this kills your performance because it alters the time the valves stay close sending the cam timing for a loop, I explained about cam profiles on my Q&A thread, but i think is relevant to mention it again, cam lobe profile is the MOST common cause of valve float, when the cam lobe start to open the valve it needs to do it smoothly so the valve will not bounce of its seat but open in a smooth way, you can however close it fast, as you can trust the spring to keep it close, obviously speed is also a big factor, as this opening and closing happen so fast at higher rpms, there is a chance that the spring will not close the valve fast enough (that is why hi revving Formula one engines relay on air to close the valve at the insane speed those engines works) also there is something called frequency and if the frequency of the spring matches the engine opening and close cycles the springs start acting weird and goes into resonance, one way to control it is with dual springs or (it was the magical solution when i used to built race engines) with a beehive shaped valve spring, any way other factor contributing to valve float is the weight and shape of the valve. Is my opinion that the valves are so small and the springs stiff enough that valve float will not happen until about 12 + k, so we have plenty of room still. Rocker arms are a seesaw lever that take the movement of the cam lobe to the valve stem, they accomplish this by having two little pads, one on top of the valve and another on the lobe of the camshaft, at high rpms this pad at the cam is getting hammered by the lobe, this pad on the rocker arm is made of hard steel(so it can take the wear) but the rocker arm itself is made of aluminum, as the rpms increase something called elasticity (which all metals have, and allows them to bend and return to its shape) will allow the rocker arm to bent slightly, and at higher rpms, this bending might be enough to allow the adjusting pad at the end of the valve to fly off and look for a nice place to land, if you are Lucky it will land some where safe and your engine will lose power and you will return home with a poorly running scooter, but if you are not so lucky it will land some where, where it it break some engine part and you will go home with a scooter with an engine that will fit loosely on a bucket. Sometime ago some very smart people discover that if you put a wheel (roller) on the rocker arm (usually at the cam end) the stress on the rocker arm goes down dramatically as the hammering dissipates by rotating the wheel and since the wheel will follow the cam lobe closer it allow for some very wild profiles on the cam without risking over stressing the rocker arm (we called this kind of rocker arm "a roller rocker arm"), and this can give a little more rpms without remorse  Now if someone were to get a cam company to make us some nice roller rockers and a wild cam we can get a hi revving scooter engine   And we can get the 9HP engine a run for its Money   But then again, I can be wrong

|

|

|

|

Post by I Heard A Rukus on Dec 11, 2006 21:49:39 GMT -5

I would gladly pay $150 for a pair of roller rockers. On a Chevy 350 (do they have those in Canada  ) a roller rocker set will get you 15-20% more power, that's insane!! They make them for Honda cars though they are pricey and pretty new. Our best bet would be to see if they make them for something else and could be converted/adapted. Like we made a roller rocker head using 2 HF CRX 8 valve heads and putting them in a 16 valve Si head. Honda used roller rockers in the HF because it was their super efficient engine in the late 80's early 90's. Those cars get 60+ MPG stock!! So I think Honda knew what they were doing. So who wants to make some custom rollers? KP |

|

|

|

Post by Dandy Dan on Dec 12, 2006 11:25:58 GMT -5

Everything you said makes sense Chanito...our valves are tiny so assuming you're correct that they won't float until 12K+ RPM then the rocker arms seem like the main thing to worry about. I talked to my brother last night and he's familar with the roller rocker arms and he explained them similar to how you did...they seem like a great thing. I guess I'll stop worrying about aftermarket valves and valve springs for now and spend my efforts researching roller rocker arms. Are roller rocker arms currently used on sport bikes ie. CBR?  As kind of a side note, I was talking to him about this modified intake port idea and he said that on serious sport bikes you can look right through the carb and see the valve. I don't think we'll be able to get ours that straight because a good deal of the port is in the head and it's still curved in there but we sure can improve it a lot. |

|

|

|

Post by Dandy Dan on Dec 12, 2006 11:32:46 GMT -5

For the roller rocker arms...is modifying a stock rocker arm an option? With the amount of stress involved with rocker arms it seems like something that you'd really want to make sure was done right but I wonder if you could cut the end off the stock rocker arm and weld the roller end from another rocker arm on? Probably not but I just wanted to check....

|

|

|

|

Post by I Heard A Rukus on Dec 12, 2006 13:13:06 GMT -5

For the roller rocker arms...is modifying a stock rocker arm an option? With the amount of stress involved with rocker arms it seems like something that you'd really want to make sure was done right but I wonder if you could cut the end off the stock rocker arm and weld the roller end from another rocker arm on? Probably not but I just wanted to check.... Yeah prolly, not. We might be able to adapt another model to ours, but there are so many design variables in a roller rocker that would have to be perfect, just think about the speed these things move! Aluminum is fine for rollers but I don't own a CNC and my CAD is a bit rusty  KP |

|

|

|

Post by chanito on Dec 12, 2006 19:55:22 GMT -5

If it was not for the big bore, i will be contacting the people at Comp cams, or dyno cams for a set or roller rocker arms and a roller cam, but if i mention something like this at home i will be chase out of the house by a rolling pin wielding wife  But anyway lets get to 10k first and then go for the 12k  And a straight thru intake track would be too wild for any street riding  but you got the right idea

|

|