|

|

Post by chanito on Sept 8, 2007 14:44:38 GMT -5

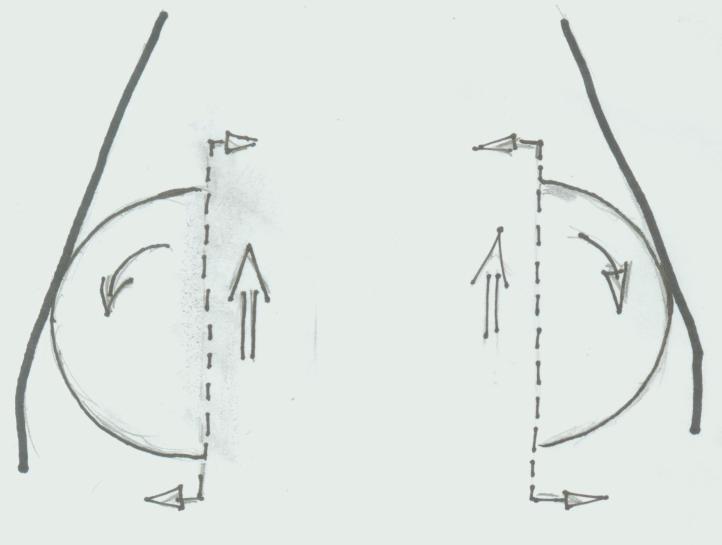

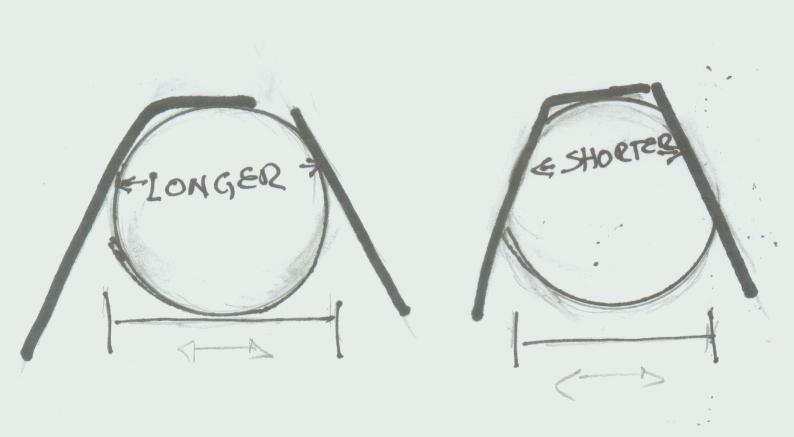

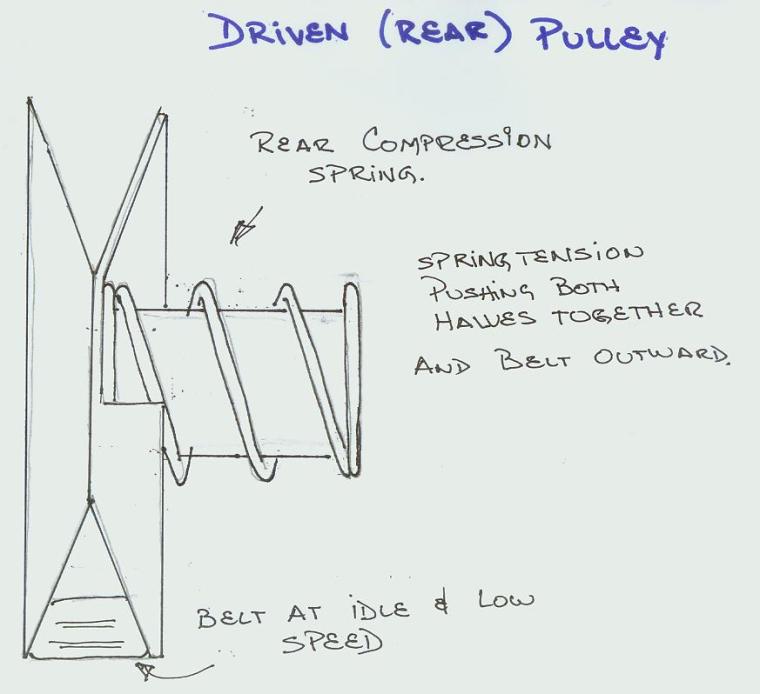

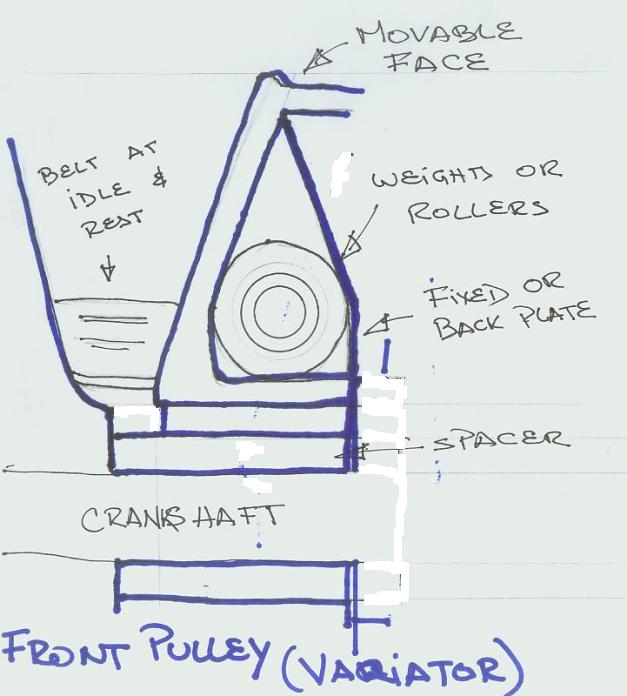

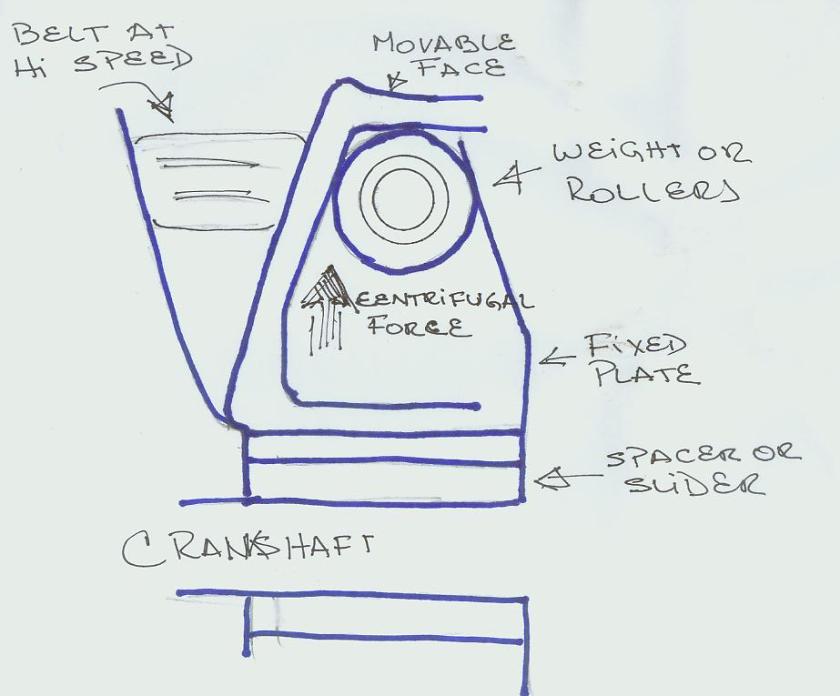

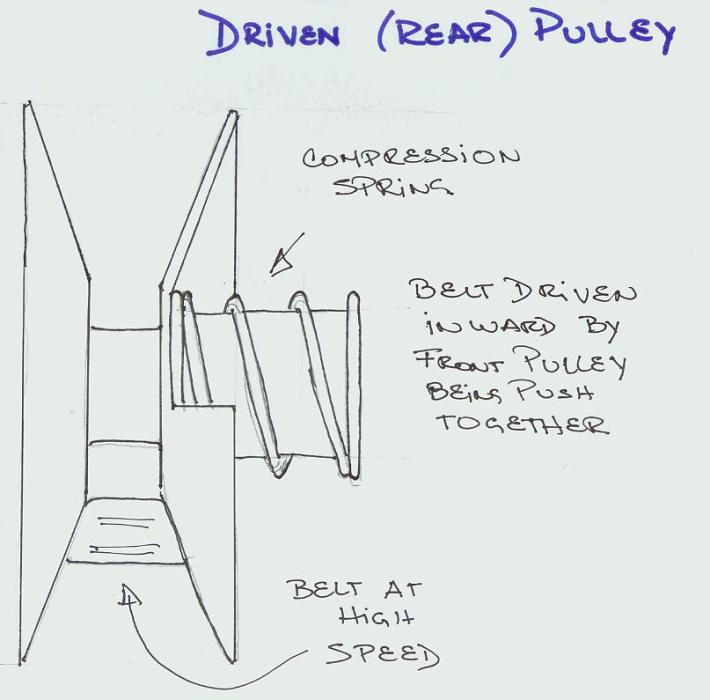

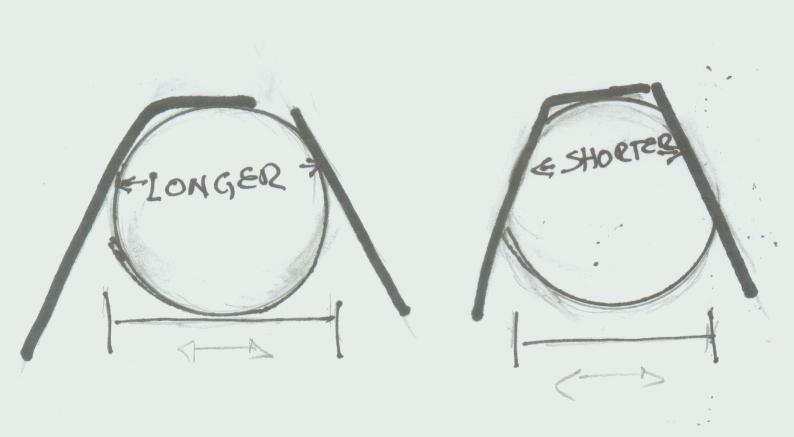

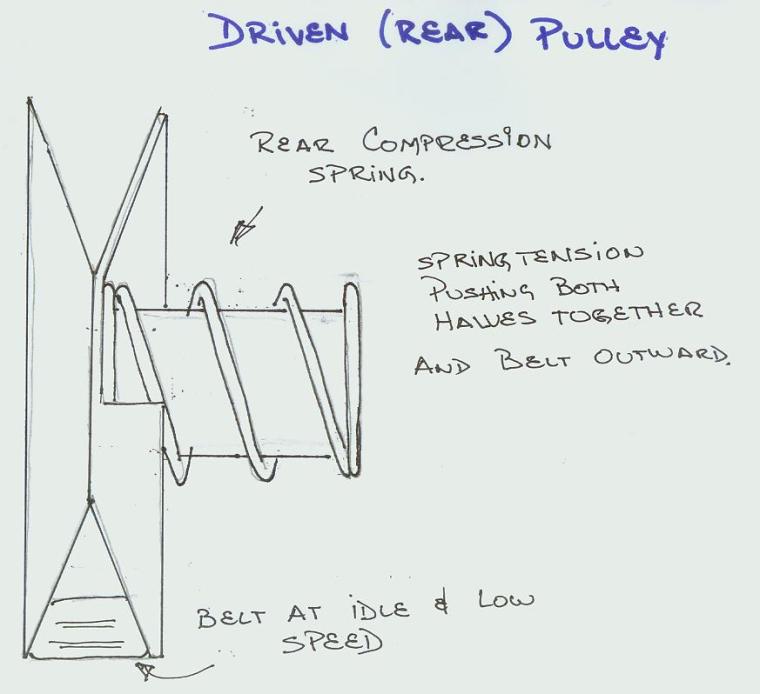

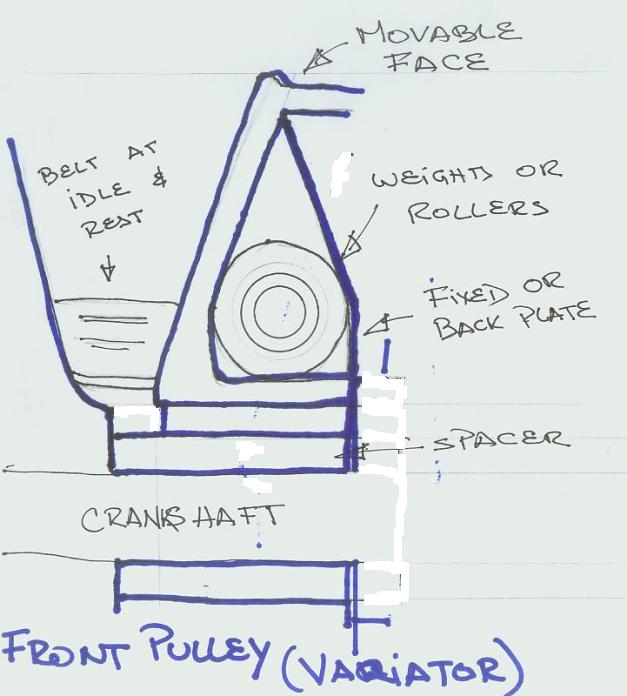

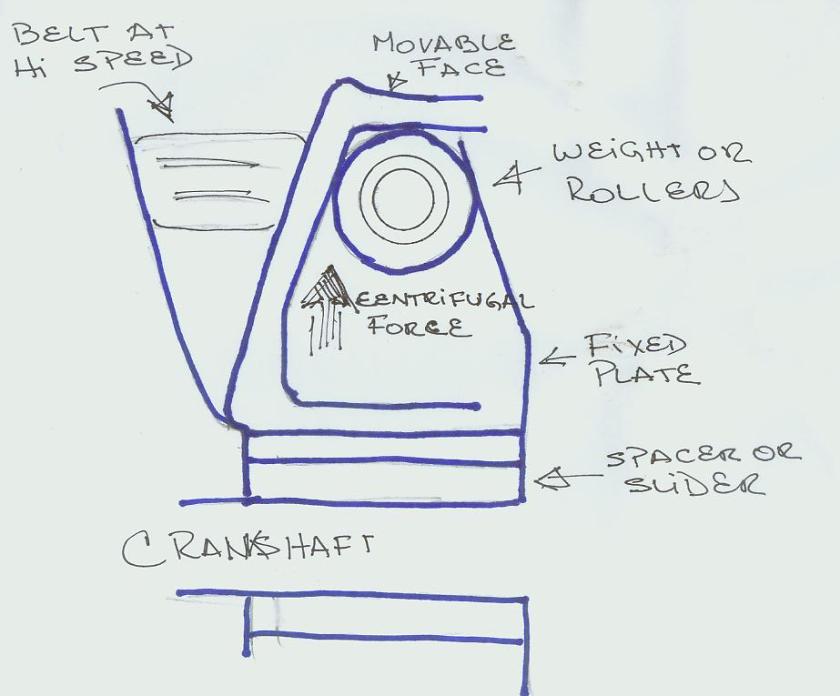

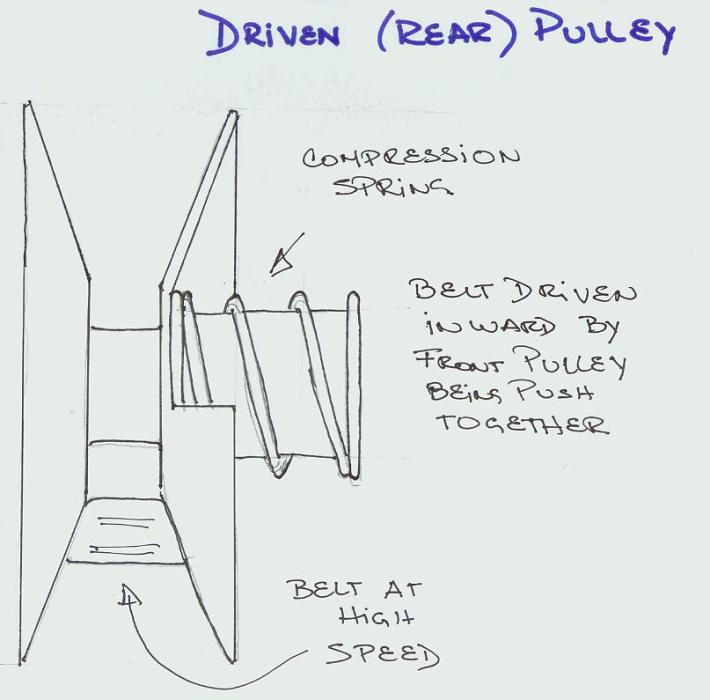

So that we all are on the same page, i have done some drawings to illustrate the basics of the kind of transmission on our scooters (ruckus/metro) i hope this will make it easier to understand how it works and if we need any more discussion on the subject. The Variator or continually variable transmission on the ruckus is similar to the set of gear commonly found on bicycles, we have two pulleys that can change the with of the groove where the bely rides, so the belt can ride lower or higher on it, at rest the belt is lower on the front pulley and out on the rear pulley  A stiff spring is used on the rear pulley to keep the two halves of the pulley closed together, pushing the belt out, and this also push the belt deep into the front pulley, as the size of the belt is such that it will only allow the belt to be out if the other end is in  the front pulley is therefore kept at rest with the belt riding in, giving us a low gearing for take off and acceleration. This front pulley which is also called the driving pulley uses a very clever design, it uses a set of rollers or weights which are the meat of a sandwich where the bread is on one side a movable face of the front pulley and on the other a bend plate. As the speed of the engine increases the centrifugal force acting on the weight start shooting them out, as they move out they push the movable face sideway, making the pulley narrower sending the belt outward,  since the belt will not grow, it will start also to compress the spring on the rear pulley as it sink into the groove, so we end up with a higher gear necessary to achieve top speed   as you can see is a very simple system that works very good, the only problem is that the rollers do not roll, so with time they start developing flat spots where they slide on the ramps, so they require replacement periodically, the weight of the rollers affect how fast those two halves of the front pulley close, the lighter the weights the higher the engine speed required to shoot them out, the weight of the movable face have a small effect due to the inertia, so the higher the weight of the movable face the higher the speed to begin the movement, but only it start moving it is of no consequence, if you see a graph of the engine speed you will notice a peak required to beat the movable face inertia, as soon as it start moving, the engine speed will drop and start rising again slowly with the speed of the vehicle  There you go Variator 101

|

|

|

|

Post by ZOOMER46 on Sept 9, 2007 4:05:17 GMT -5

heres a video of it on youtube www.youtube.com/watch?v=sXnpNKxIbh4chanito,your pics have gone awol?  nice work btw,i like the sandwich explanation, ;D i will never look at my lunch the same again  |

|

|

|

Post by rustythescoob on Sept 11, 2007 6:26:25 GMT -5

Thank you, that is awesome! The bending of the plate was the part that I couldn't get a handle on.

|

|

|

|

Post by Dandy Dan on Sept 11, 2007 18:59:44 GMT -5

Nice pics Chanito! That makes a lot of sense. I didn't realize that the rollers don't roll at all but I guess that makes sense since there is so much force squeezing them.

|

|

|

|

Post by chanito on Sept 11, 2007 20:28:44 GMT -5

The rollers can not roll because in order to roll they will need one of the wall to move, being stacionary means that as the roller try to roll, the other side will try to roll the wrong way, preventing it from rolling

|

|

|

|

Post by ZOOMER46 on Sept 14, 2007 0:35:16 GMT -5

and that explains the flats that develope on the rollers....

ahhh i see..

|

|

ezp

n00b Ruckster

Posts: 43

|

Post by ezp on Sept 28, 2007 13:02:11 GMT -5

I have a question: what does it matter if flat spots develop on the rollers? Wouldn't they still be able to slide anyway? And what do flat spots do to speed? thanks again....

|

|

|

|

Post by varroa on Sept 29, 2007 4:54:30 GMT -5

I have a question: what does it matter if flat spots develop on the rollers? Wouldn't they still be able to slide anyway? And what do flat spots do to speed? thanks again.... the bigger the spots, the narrower they (rollers) get, therefore even when they are pushed all the way out, they still can't push the boss as much, therefore the boss doesn't squeeze the belt as much, therefore it doens't ride as high, therefore less speed. yeah, i could insert more "therefore", but it got old quick, and not funny anymore after so many "therefore". |

|

ezp

n00b Ruckster

Posts: 43

|

Post by ezp on Sept 29, 2007 9:16:54 GMT -5

ahhhhh-hah! Therefore, you make sense!!! I've always wondered about this, thanks!!

|

|

|

|

Post by chanito on Sept 30, 2007 15:26:34 GMT -5

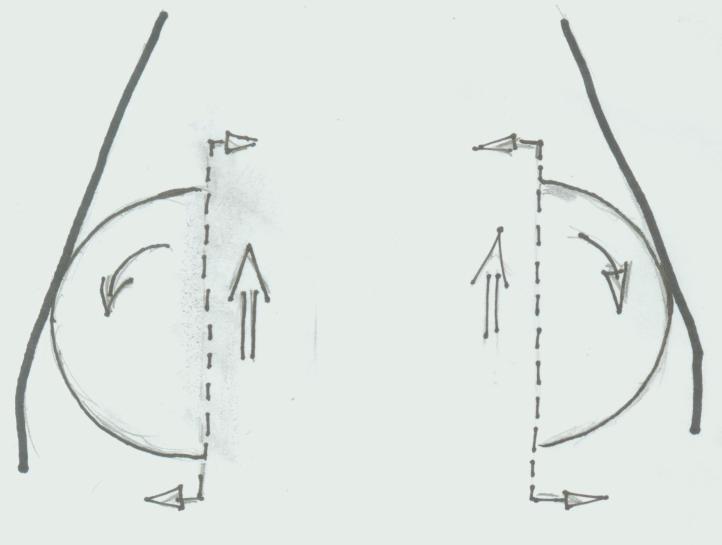

I have decided to illustrate this matter of the non rolling rollers, so here are some more bad drawings that hopefully will help understand  I have cut the roller in half, each with its corresponding ramp, as you can see, in order for the half facing the sliding face, to roll outward it need to rotate counterclockwise, but for the half facing the stationary ramp it need to rotate clockwise, now if we joint both halves we will notice that in order for the roller to roll out it need to rotate both ways at the same time, and since it can not do that, it decides to not roll at all  As the roller wears down it develops flat spots, they limit your top speed by not separating the face far enough, as it can not push the movable face as far out as a new roller, and that kills your top speed, also as it develops flat spots, friction increases, requiring more speed to move out, acting like heavier rollers killing your acceleration  Making your scooter perform terrible  one of the best performance mods for an old scooter is just a new set of rollers and a new belt ;D The reason i am making so much emphasis on variator and carburetors, is that they are the most misunderstood parts of the scooter, and i keep reading here and in other forums, people giving wrong advice about both

|

|

|

|

Post by ace1969 on Oct 2, 2007 21:20:21 GMT -5

Chanito does this mean that the sliding wedge weights would be better or worse for a ruckus?

|

|

|

|

Post by chanito on Oct 3, 2007 18:50:14 GMT -5

This is obviously just "my opinion" wedges would be worst for a ruckus. The wedge design type of weights outlast the roller kind and are smoother, but like most things in live, there is a trade in, they have more friction (bigger surface being ground against the ramps) so they require more power and speed to operate, since the scooter is only 50cc the loses because of the extra friction outweights the advantages, however on bigger scooter, the trade in is worth it

|

|

|

|

Post by ace1969 on Oct 4, 2007 20:38:08 GMT -5

I knew you would have a logical answer.

|

|

kat

n00b Ruckster

Posts: 7

|

Post by kat on Oct 9, 2007 4:27:36 GMT -5

The rollers can not roll because in order to roll they will need one of the wall to move, being stacionary means that as the roller try to roll, the other side will try to roll the wrong way, preventing it from rolling  Is this why sliders were developed? I wonder if they are teflon coated? |

|

|

|

Post by chanito on Oct 10, 2007 20:10:58 GMT -5

Yes Kat that is the reazon they were invented as the rollers do not last that long, sliders are almost a put them and forget them kind of deals. and some have very fancy and hi tech plastics, on the sliders you DO WANT friction as it is necesary to make the variator go thru all the "gears" because if the slider slide too easy the transmition would go from 1 to 5 (  skiping all the ratios between roll out and max opening) giving very bad performance

|

|

|

|

Post by eq1 on Oct 11, 2007 0:05:09 GMT -5

...on the sliders you DO WANT friction as it is necesary to make the variator go thru all the "gears" because if the slider slide too easy the transmition would go from 1 to 5 (  skiping all the ratios between roll out and max opening) giving very bad performance I don't see how this is the case. The main thing keeping the variator from upshifting is resistance caused by rider weight and road conditions versus the power available. For example, if you have the scoot on the stand and turn the throttle, the variator will open quickly and reach top gear quickly (ignore the rear compression spring for now; it's superfluous). If you're sitting on it, on the road, the engine has to work to overcome the resistance of your body weight, turning the wheels, etc. If you have a big bore, the extra power overcomes the resistance of your body weight et al more quickly and the variator thus upshifts more quickly - i.e. because the power can handle a taller gearing more easily... I don't see where the ramp plate guides factor into any of this. If there's too much friction, such as what happens if you put the blue Polini guides in upside down, it will interfere with the variator opening easily... |

|

|

|

Post by eq1 on Oct 11, 2007 9:04:48 GMT -5

I wish I logged in when I wrote that above, cuz then I could delete it. I was on my way home, on my scoot, thinking about variators, when it dawned on me that there's no way chanito could be saying what I thought he was saying. I reflected some more, thought 'sliders', 'ramp guides'. The word 'wedges' came into my head and I realized he must've been talking about those wedge weights. Anyway, sorry I didn't read the whole thread. Forget the above post ever was written.

|

|

|

|

Post by Kami no Chiizu on Oct 11, 2007 12:48:42 GMT -5

I could delete it if you wanted...

|

|

|

|

Post by chanito on Oct 11, 2007 16:40:45 GMT -5

...on the sliders you DO WANT friction as it is necesary to make the variator go thru all the "gears" because if the slider slide too easy the transmition would go from 1 to 5 (  skiping all the ratios between roll out and max opening) giving very bad performance I don't see how this is the case. The main thing keeping the variator from upshifting is resistance caused by rider weight and road conditions versus the power available. For example, if you have the scoot on the stand and turn the throttle, the variator will open quickly and reach top gear quickly (ignore the rear compression spring for now; it's superfluous). If you're sitting on it, on the road, the engine has to work to overcome the resistance of your body weight, turning the wheels, etc. If you have a big bore, the extra power overcomes the resistance of your body weight et al more quickly and the variator thus upshifts more quickly - i.e. because the power can handle a taller gearing more easily... I don't see where the ramp plate guides factor into any of this. If there's too much friction, such as what happens if you put the blue Polini guides in upside down, it will interfere with the variator opening easily...  I do not quite get you, but the action of the weights (rollers) in the variator is mainly based on the weight of the rollers and the speed of the engine (the variator is mounted straight to the crank, so engine speed equals variator speed), since they are enclosed on the ramps friction also plays a role. The reazon the variator works faster on the stand, is that since there is no load on the engine, the engine will spin faster making the weights go outer faster, if you put a load on the engine, the engine will spin slower so the weight will not shift the variator as quick, so no matter the load the weights should spin the same if the engine is at 7k with or without load, so the variator position will be the same  |

|

eq

Junior Ruckster

Posts: 74

|

Post by eq on Oct 16, 2007 0:14:31 GMT -5

Let me try to take a quick stab at this... You write:

"...no matter the load the weights should spin the same if the engine is at 7k with or without load, so the variator position will be the same."

This is the part that I would 'debate', though I can't say I have it all clearly in my head. My understanding is that the gearing is NOT the same at a given engine speed, say 7k, independent of the load. A heavier load means more resistance, and more resistance causes the variator to downshift, or perhaps fail to upshift, as much as it would with a light load, say a light rider or traveling down hill.

Picture a heavy rider going up hill. The engine will try to spin as fast as possible as it tries to overcome the resistance. The variator is 'stuck' in the middle of this battle between engine speed and power on the one hand, and the road and rider-weight resistance on the other. Instead of a fixed gear ratio and power being transfered directly to the wheels commensurate with that fixed ratio, the variator will be forced to stay closed (or resist being opened) and the gearing forced to stay low. It's some sort of equilibrium that is being attempted. Say the engine reaches 6K at a gearing midway on the front pulley under these conditions.

Now, picture the rider reaching the top of the hill and onto flat ground. The flat ground reduces resistance, the variator can open more easily - it can upshift. Say you tried to hold rpms constant at 6K while you transitioned to flat ground. The variator would upshift - to a gearing perhaps two-thirds of the way up the front pulley, and your speed would increase... The tendency would be for the engine to seek its max power rpms - and the variator is a part of that tendency. The variator won't upshift if there's more resistance 'on the wheels side' of the drive than on the 'engine side'. If there's more 'resistance' on the engine side (or less resistance on the wheels side) then the variator will upshift... These terms are certainly not the most appropriate, but I don't know any others...

Now if this heavy rider were to start going downhill, the variator would upshift even more - maybe not all the way to max gearing, but closer to it (the variator design and weight-roller weights kind of set a range of gearing options - so at 6K it still may be impossible for the variator to open all the way, regardless of load/resistance). RPMs could still be held at 6K, but speed increases even more. If the variator had heavy weights it would upshift more (not exactly faster; just more). I think, at given weight-roller weights, it's like the whole gearing is shifted left to right, from low to high, over time. So if with 6g you were hitting 1/2 way up the pulley at 6K (up the hill), with 5g you might be hitting 3/8ths up the pulley at 6K - and since there's more power at higher rpms, the engine would be able to spin faster - so you might top out at 6800 rpms at 1/2 way up the pulley instead of 6K...

Anyway, that's my understanding. The gearing isn't always fixed at certain engine speeds; it depends on the load and engine power available, given a certain range of gearing options set by the variator design and weight-roller weights (most of this applies to clutch-engaged conditions).

|

|

So that we all are on the same page, i have done some drawings to illustrate the basics of the kind of transmission on our scooters (ruckus/metro) i hope this will make it easier to understand how it works and if we need any more discussion on the subject.

So that we all are on the same page, i have done some drawings to illustrate the basics of the kind of transmission on our scooters (ruckus/metro) i hope this will make it easier to understand how it works and if we need any more discussion on the subject.

as you can see is a very simple system that works very good, the only problem is that the rollers do not roll, so with time they start developing flat spots where they slide on the ramps, so they require replacement periodically, the weight of the rollers affect how fast those two halves of the front pulley close, the lighter the weights the higher the engine speed required to shoot them out, the weight of the movable face have a small effect due to the inertia, so the higher the weight of the movable face the higher the speed to begin the movement, but only it start moving it is of no consequence, if you see a graph of the engine speed you will notice a peak required to beat the movable face inertia, as soon as it start moving, the engine speed will drop and start rising again slowly with the speed of the vehicle

as you can see is a very simple system that works very good, the only problem is that the rollers do not roll, so with time they start developing flat spots where they slide on the ramps, so they require replacement periodically, the weight of the rollers affect how fast those two halves of the front pulley close, the lighter the weights the higher the engine speed required to shoot them out, the weight of the movable face have a small effect due to the inertia, so the higher the weight of the movable face the higher the speed to begin the movement, but only it start moving it is of no consequence, if you see a graph of the engine speed you will notice a peak required to beat the movable face inertia, as soon as it start moving, the engine speed will drop and start rising again slowly with the speed of the vehicle