|

|

Post by Dandy Dan on Jan 26, 2006 17:21:15 GMT -5

Are you gonna do the cam Wicked? You sounded a bit scared of it in your last post. It is a bit of work and there are few things you gotta keep in mind but it's really not that bad and if you get hung up you can just stop and post on here and I'll help you out.

|

|

|

|

Post by Kami no Chiizu on Jan 26, 2006 17:57:42 GMT -5

It's amazing how long a thread can get with so little spam.

This thread is keeping me on the edge of my seat.

|

|

|

|

Post by wickedsf on Jan 27, 2006 1:04:08 GMT -5

Actually I ordered it on Tuesday:) Now I'm deciding if I'm going to try put it on myself or bring it to someone. So far everything on my scoot I've done myself. How long do you think it will take?

|

|

|

|

Post by Dandy Dan on Jan 27, 2006 12:28:58 GMT -5

I'd suggest doing it yourself but get the shop manual. Give yourself the better part of a Saturday and just take your time and keep things organized. When you remove hoses and wires just throw some masking tape around the end saying where it came from. There isn't any one part that's hard, you just need to stay organzied and it should go fine. If you do get hung up just post on here and we'll help. If you really get cold feet you can always take it in later.

|

|

|

|

Post by chanito on Jan 28, 2006 3:32:12 GMT -5

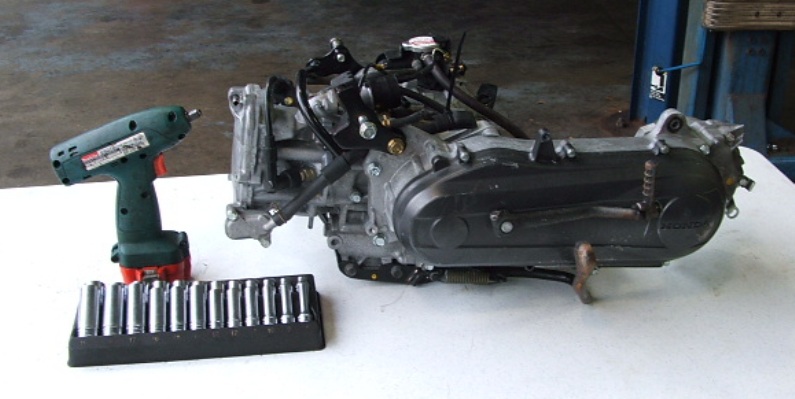

Yes i finally got the engine, i am getting ready to go to Daytona for the 24 hours race, i will take the engine apart on monday and will post pictures

|

|

|

|

Post by timberwolfmadcat on Jan 28, 2006 14:29:31 GMT -5

Sweet  Best of luck chanito   , Hopefully this will allow us to crack the 90 km/h barrier   . Id settle for 85 though  |

|

|

|

Post by wickedsf on Jan 28, 2006 16:42:56 GMT -5

Thanks Dan. I guess I better order a service manual.

|

|

|

|

Post by Dandy Dan on Jan 29, 2006 1:16:20 GMT -5

Now that the Ruckus has changed for 2006 you can get the 2003-2005 manual on ebay for cheap. Also check out helminc.com and repairmanuals.com. I forget which of those 2 sites I ordered from but one is way less shipping to Canada than the other.

|

|

|

|

Post by timberwolfmadcat on Jan 30, 2006 16:17:17 GMT -5

Congrats Chanito on the Promotion!!!!!  Well deserved |

|

|

|

Post by chanito on Jan 30, 2006 20:30:54 GMT -5

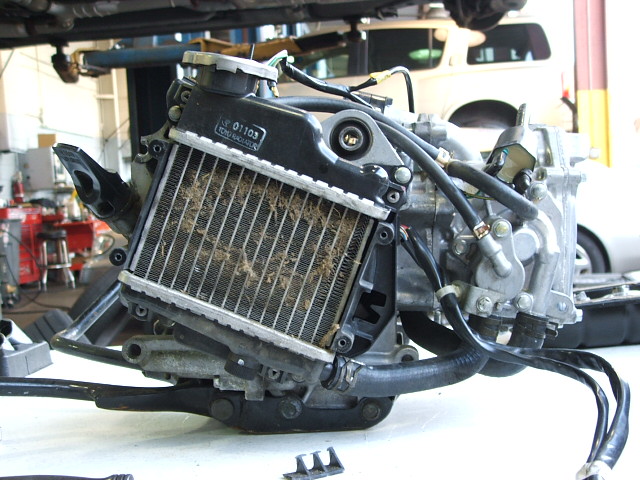

:)The race was great! I finally took the engine apart  It is very good shape, one of the ears for the muffler is broken and the valves needed adjusment so the intake will need to be reseat, but it was well maintained so it should do a great starting point for the big bore project  tomorow i will take the block to the machine shop to have it check to be sure it can be cutted without problems  I will post more pics tomorrow ;D |

|

|

|

Post by Dandy Dan on Jan 30, 2006 20:33:24 GMT -5

Cool pics Chanito. Why is the variator area all white? Is that grease or is it mold or something?

|

|

|

|

Post by Dandy Dan on Jan 30, 2006 20:34:25 GMT -5

the valves needed adjusment so the intake will need to be reseat Why are you going to reseat the valve? Is it that bad? Chanito: Do you need the skidplate/centerstand for anything? The holes in my skid plate where the stand goes through have turned into ovals after 27,000kms and as a result my scooter tilts like it's on a kickstand when it put in on the centerstand. It's really tippy and easily tips over if you bump the wrong side. I took the centerstand and skid plate totally off now that I have a kickstand(because I can't figure out how to seperate them, any ideas? I got the clip out but I can't slide the pin out...maybe it's just too rusty) but I'll need to score some new or used ones before I sell it in a couple months. If you want them that's fine but if not maybe you could ship them at the same time is the piston when that's ready. Chanito, do you think it's a good idea to keep the skidplate on the underside of the engine? I can see it being a good idea if you offroad it or something but for around town commuter use it seems like overkill and one way to save a little weight. |

|

|

|

Post by Dandy Dan on Jan 30, 2006 20:46:02 GMT -5

one of the ears for the muffler is broken That sucks! Did the seller tell you this? That's actually the same tab I'm having problems with. My lower muffler tab broke off so all the weight was on the top bolt and it ended up shearing off. I drilling through it and tried to extract it but my hardened steel extractor broke off inside. I ended up drilling out all around it so I had a huge ugly hole in the tab. Then I filled that up with JB Weld and then drilled a stock sided hole in the JB Weld. Lastly I grinded the back of the tab flat and then used a washer and nut to hold the bolt tight. What do you think you are going to do about this tab? You could fabricate one from aluminum and Tig weld it on there...or I guess you could never fix it because this engine might never see regular use. Judging from my experience with just the lower bolt you can go a few hundred miles before It breaks. [Dans Muffler Background] Just to clarify, my upper bolt actually fell out first so I rode around with just the lower bolt for a while. Then the lower muffler tab broke off so I replaced the top bolt and ran with just that until the top bolt sheared off. Then I got the steel muffler tab welded back on and fixed the upper hold via JB Weld so know I'm back in business except during all this my muffler broke off where the header enters and they did a super crappy weld job on it so it's very ugly. I'm gonna throw my 2006 muffler on there before I sell it since I have the Yosh and use the 03 beater for testing only. [/Dans Muffler Background] |

|

|

|

Post by chanito on Jan 30, 2006 20:51:39 GMT -5

;D Sure you can have the skid plate, i was going to make an engine stand out of it, but i will trade yours for it. the idea is that the skid plate also acts as a stress reliever for the sump of the engine, and will prevent any crack developing on the aluminum crankcase, very good idea to keep if you drive on rough roads ;D The white stuff is aluminum rust, is just on the surface so i will not worry about it  This is what happens when your valves are too tight, compression will leak because the valve does not seal perfectly  |

|

|

|

Post by timberwolfmadcat on Jan 30, 2006 21:02:59 GMT -5

|

|

|

|

Post by Dandy Dan on Jan 30, 2006 21:06:40 GMT -5

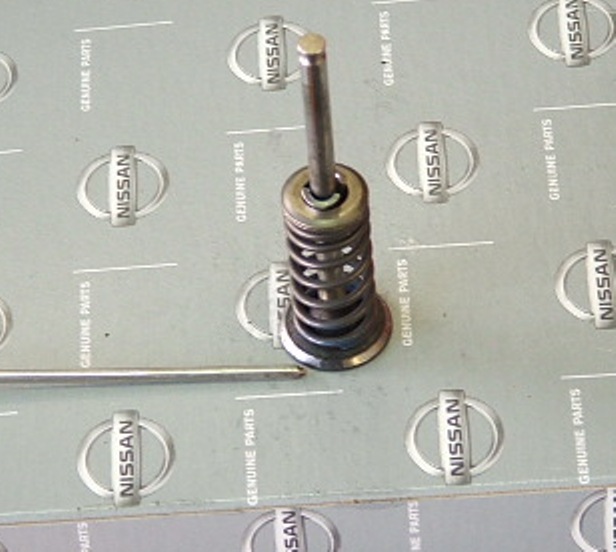

Chanito: I don't understand what's wrong with the valve shown in that pic? Is that a dirty/worn spot right at the front indicating a leak?

Did you use a valve spring compressor to remove the valves or did you just squash them yourself?

|

|

|

|

Post by chanito on Jan 30, 2006 21:12:43 GMT -5

The spot is part of the valve that was not seating, as you can see the rest of the valve is shiny, it should be shiny all the way around, that spot means that gasses were leaking thru that opening  NO they are too small for my valve spring compresor, i just lie a wrench across and press the valve down, maybe i will post a picture so it will be easy to understand ;D

|

|

|

|

Post by Dandy Dan on Jan 30, 2006 21:20:36 GMT -5

Gotcha! I first gave the valve a little tap to 'break the seal' and then I used the appropriate socket to press down on it.

|

|

|

|

Post by chanito on Jan 30, 2006 21:30:19 GMT -5

:)Tomorrow i will go to the machine shop, and then i will sent my parts, so they can make the pistons, and now the changes in the site, too much excitment  |

|

|

|

Post by Dandy Dan on Jan 30, 2006 21:33:53 GMT -5

too much excitment  Yeah I feel like I'm 3 years old again  |

|