|

|

Post by chanito on Feb 1, 2006 19:35:03 GMT -5

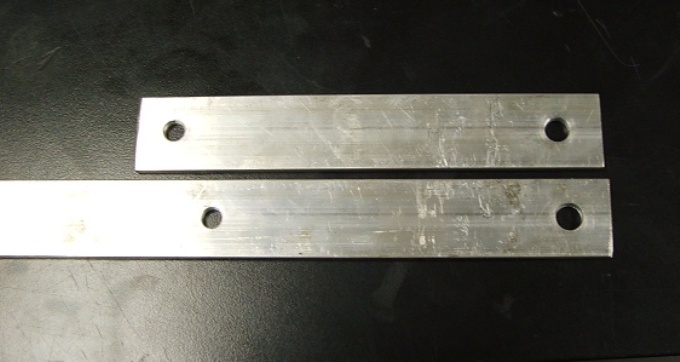

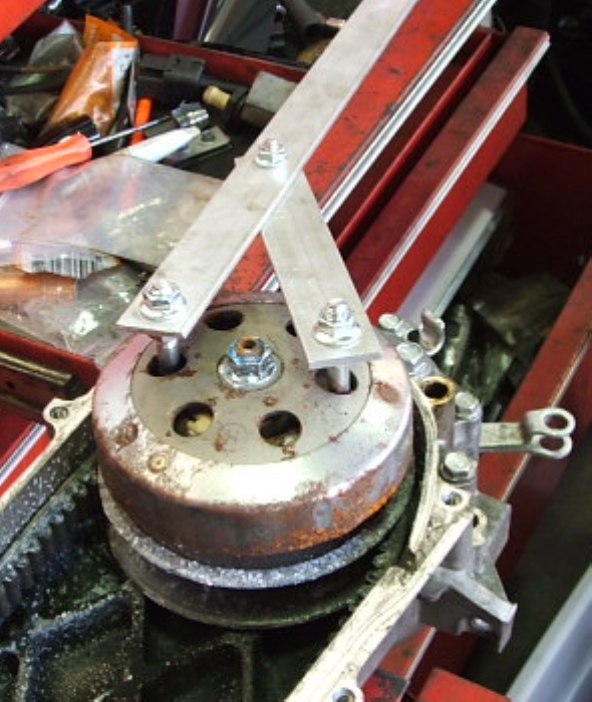

OK here is the list of materials 1 36" long aluminum strip 1/8"x1" (that is as small as i could get it) 2 bolts 8mm x 40mm 4 8mm nuts 1 6mm x 15mms 1 6mm nut 2 12mm wrenches drill and 1/4" and 5/16" drill bits hacksaw here are the materials i got from Home Depot in exchange for 8 dollars  you need to cut a six inches long piece from the strip  you also will need to cut the heads of the two 8mm bolts and file the shanks to smooth them  now you need to drill a 1/4" hole and one 5/16 hole in the six inch strip at both ends, also you have to do the same to the long strip, as you can see i made then at different lengths but you can made them the same length, then you will need to install the modified 8mm bolts on the out side of the strips and secure them with the nuts, use the 6mm bolt as a hinge pivot, 6mm seems small, but should be plenty for the torque figures in the variator system  and this is the correct way to use your tool to loosen or tighten the variator nut, just make sure the bolts go into the recesses in the variator fins  you can also use this tool for the clutch  you can make the longer strip as long as you want i think 15-18" long is perfect ;D

|

|

|

|

Post by Dandy Dan on Feb 1, 2006 22:16:49 GMT -5

Cool write up Chanito...when i doubt make things beefy. I was actually able to find metal strips like you made in the brackets/hinges section that came in different lengths and already had holes drilled in them. However the smaller pieces had smaller holes so I still needed to drill things out a bit.

BTW, the inside of that drive unit looks pretty gross....I thought mine looked sketchy.

|

|

|

|

Post by cabuco2006 on Feb 3, 2006 21:33:10 GMT -5

chanito ..how u get the clutch nut off...its on their real tight...i have my universal holder..but its too tight...

|

|

|

|

Post by chanito on Feb 3, 2006 21:37:06 GMT -5

Spray some penetrating oil, get a six point 14mm socket, a big breaker bar and some elbow grease ;D As you can see the clutch was rusted so just spray that nut liberally and give it some time to penetrate

|

|

|

|

Post by jrcanoe on Feb 4, 2006 10:37:41 GMT -5

Thanks for doing the homework. Now can I have your lunch money! so I end up with this tool for free.  |

|

|

|

Post by wonderdog on Feb 4, 2006 11:02:37 GMT -5

I used a strap wrench. It worked but was kinda unwieldy. I'll build one from your pics. Thanks a bunch!

Wonderdog

|

|

|

|

Post by timberwolfmadcat on Feb 7, 2006 11:40:27 GMT -5

I didnt find the clutch nut too hard to take off, i got an old bar torque wrench thats 1.5ft long though, with the smaller wrench, i couldnt get it to budge

|

|

|

|

Post by chanito on Feb 7, 2006 21:22:21 GMT -5

Yeah! i am still amaze at the wonder of the lever, if it is tight, get a longer wrench ;D ;D

|

|

ZoomZoom

Ruckster

'05 Ruckus, '97 Polaris 400L 4X4

'05 Ruckus, '97 Polaris 400L 4X4

Posts: 251

|

Post by ZoomZoom on Feb 8, 2006 20:37:09 GMT -5

Nice how-to. Not as fancy as my tool but I like it.  |

|

|

|

Post by chanito on Feb 12, 2006 13:03:59 GMT -5

Nice how-to. Not as fancy as my tool but I like it.   I tryed to make it fancy as your, but i came up short  , however this will work on the whole drivetrain ;D |

|

|

|

Post by sasquatch on Feb 13, 2006 4:12:14 GMT -5

hi all. new to the site.

Guess someone beat me to it. I just built a variator tool yesterday just about the same as the one posted. Only difference is the length of the short arm which I made 4 inches and the pivit bolt is 3/8” on mine. I tired to include a picture but don’t know how to get it to work.

|

|

|

|

Post by tedsmini on Feb 13, 2006 4:46:31 GMT -5

|

|

|

|

Post by chanito on Feb 13, 2006 18:40:55 GMT -5

hi all. new to the site. Guess someone beat me to it. I just built a variator tool yesterday just about the same as the one posted. Only difference is the length of the short arm which I made 4 inches and the pivit bolt is 3/8” on mine. I tired to include a picture but don’t know how to get it to work.  Welcome to the forum, and please feel free to post any tool idea and pics of your ride ;D ;D |

|

|

|

Post by chanito on May 16, 2006 19:30:31 GMT -5

|

|

|

|

Post by Dandy Dan on May 17, 2006 8:29:03 GMT -5

Good Stuff Chanito! Back when I did it I used a socket which worked okay. For one of the valves I need to tap it with a hammer to 'break the seal' and then I could do it by hand.

|

|

bango707

Junior Ruckster

Southern Cali Ruk Rider!

Southern Cali Ruk Rider!

Posts: 66

|

Post by bango707 on Jun 1, 2006 16:49:32 GMT -5

so a socket will work just fine? I would much rather buy a socket wrench or a variator tool than try my luck at making a one. I thought I read something a while back about someone selling variator tools? If anyone knows where I can find one I would appreciate it.

|

|

|

|

Post by Dandy Dan on Jun 2, 2006 9:14:27 GMT -5

Yeah I'm selling them for $15 plus $8 shipping. They look a lot like what Chanito posted above only with a rubber dipped handle in Racing Red.

|

|

|

|

Post by chanito on Jun 2, 2006 23:47:35 GMT -5

Yeah! DD tools rock, the need for a tool for compresing the valve spring is to have a window so you can reach the valve keepers, with a socket there is no way to reach in there

|

|

bango707

Junior Ruckster

Southern Cali Ruk Rider!

Southern Cali Ruk Rider!

Posts: 66

|

Post by bango707 on Jun 3, 2006 0:18:28 GMT -5

I see. What payment methods do you accept Dan?

|

|

|

|

Post by jedisabre7 on Jun 3, 2006 16:07:36 GMT -5

|

|